3D scanning is used in the automotive field

Customer requirements:

Body in White refers to the welding assembly of the body structure and the panel that has been welded but not painted, includinga hood, a car body anda trunk.

Solution

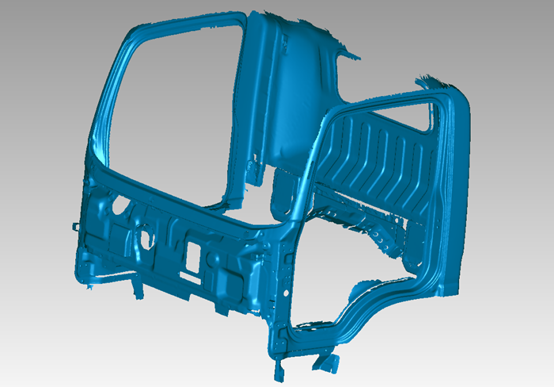

3D scanner is used to detect the complete body in white, whether it is a car door, hood or the entire body. The surface data or size of the body in white is obtained through 3D laser scanning.

The detection results are feedback to the production department, and then the on-site engineering equipments are adjusted and processed to ensure product quality, so that the various parts of the car meets engineering requirements.

Implementation steps:

HyperScan directly completes the connection of equipments and scene construction in the body in white, which perfectly solves the problem of difficult movement of the workpiece.

The optical tracking 3D scanning system is not affected by the complex environment such as vibration, and it quickly obtains accurate 3D data on the surface of the workpiece.

The scanner quickly completes the acquisition of 3D data of the car body 480,000 measurements/second.

Operation time: After 32 minutes, complete data acquisition.

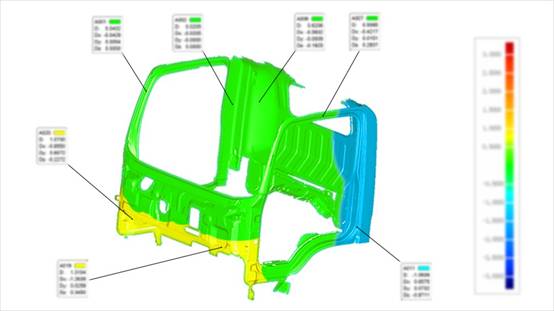

Compared with CAD data, a deviation map is generated, and the deviation trend between the car body and the CAD data intuitively displays in different colors.

Application equipment:

The combination of optical tracking 3D scanning system HyperScan 717 and Geomagic professional detection software can easily solve the requirements of the detection.

HyperScan 717 can efficiently obtain data, and Geomagic can quickly complete the analysis of the detection.

Summary of working hours:

The scanning and testing took 50 minutes in total, and among the time data collection took 32 minutes and data testing took 18 minutes. The efficiency and accuracy of detection have been unanimously recognized by customers.