Interpret inspection of vehicle from

Because "Pegasus" directed by Han Han was premiered on major Internet platforms, allow viewers to experience the charm of rallying again.

The car of the protagonist in the film accidentally crashed the day before the race, but relying on modern industrial manufacturing technology, it took a night to reassemble it.

This is impossible in reality!

But if assembling a family car, the modern flow line can be completed in a few minutes. This is not only due to advanced assembly equipment, but also requires efficient quality inspection to escort it.

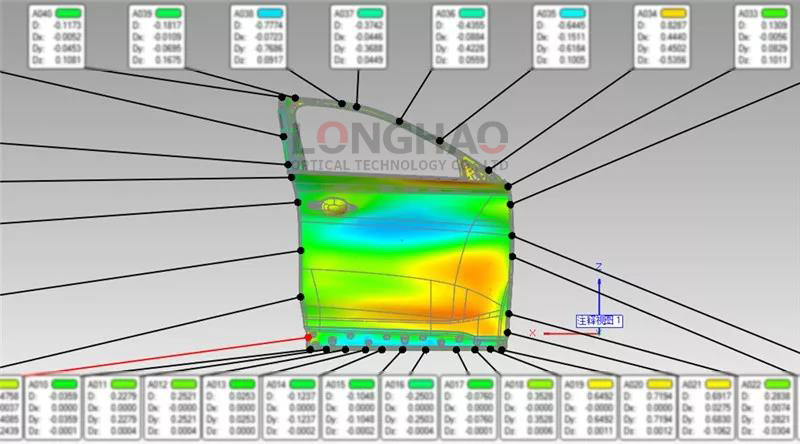

Nowadays, most main parts of automobile bodies are stamped by steel plates and welded, including the doors. Due to the elasticity of the sheet steel , partial position of the car door, especially where there is a curvature, is easy to produce deviations in the manufacturing process, which directly affects the normal installation of the car door and seriously affects the overall efficiency of automobile manufacturing.

Therefore, how to obtain an accurate deviation value and adjust the car door in time is very important.

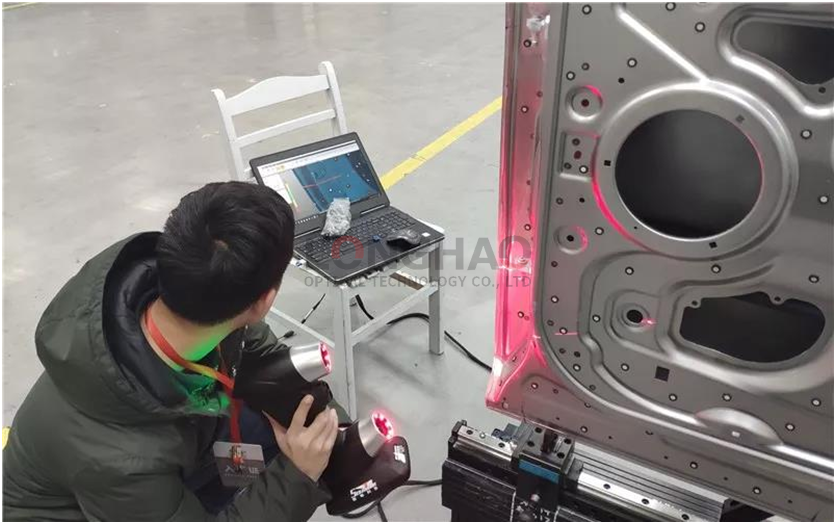

PRINCE handheld 3D scanner, it is a world first red and blue laser working mode, which takes into account the portability, flexibility and efficiency of handheld 3D scanners, and the high resolution and high detail of photogrammetry 3D scanners.

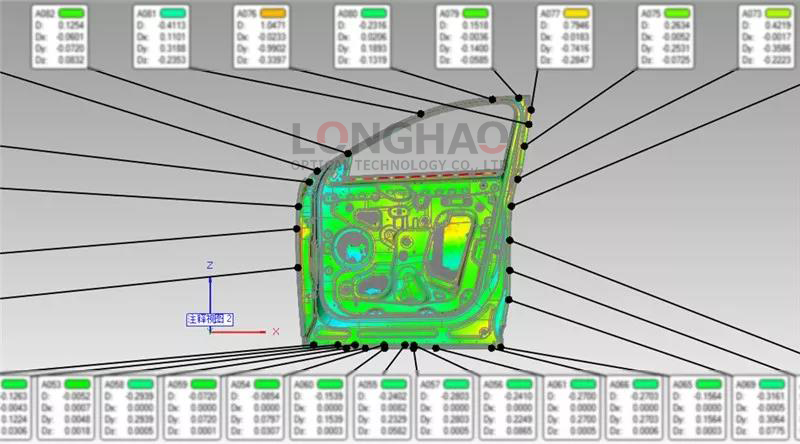

Cooperate with MSCAN photogrammetry system to eliminate accumulated errors, effectively improve the accuracy of omnibearing scanning of large workpieces, quickly and accurately obtain three-dimensional data of SUV doors, and quickly obtain the overall deviation value through modular comparison.

Inspection process

STEP1:Stick mark points, MSCAN photogrammetry system captures positioning points.

STEP2:PRINCE quickly scans the car door, and the computer displays the scanned data in real time.

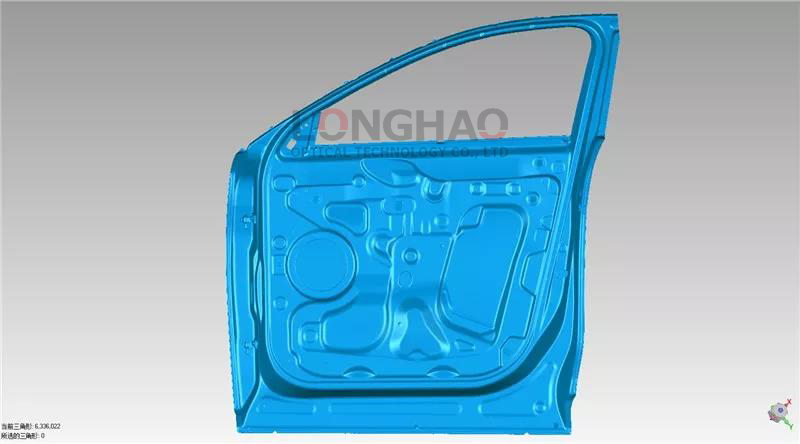

STEP3:Obtain STL data of the door.

STEP4:Compare with the data of car door modeling.

STEP5:Quickly obtain the deviation value of the surface of the car doors.

Summary:

PRINCE handheld 3D scanner and MSCAN photogrammetry system have great advantages in scanning and acquiring 3D data of large workpieces.

Not only the quality inspection of the car doors is completed quickly and accurately, but the quality inspection of the entire vehicle is not a problem. It can help automobile manufacturers and effectively improve the overall efficiency of automobile manufacturing.