FAQ Of Longhao

- What is reverse engineering?

-

Simply, make a physical product analyzed from the appearance to the interior to obtain data results, including size, features of shape, characteristic, and material, etc.

Further discussion, what is 3D reverse engineering?

Through the use of 3D digital optical equipment, the geometric surface of the object can be quickly obtained, including 3D scanning, X-Ray, computed tomography, and ultrasound. These precision instruments quickly collect the surface of the object and the internal point clouds, and they form a model through calculation of the software. This process is called 3D reconstruction, and it is also known as the construction of geometric surfaces. If the scanner can obtain the surface color, users can stick texture mapping on the reconstructed surface.

LongHao has a one-stop process capability, and a 3D entity is collected, analyzed, designed, manufactured, processed, inspected, and verified back and forth.

- Know the basic specifications of the scanner-what is the difference in resolution and accuracy?

-

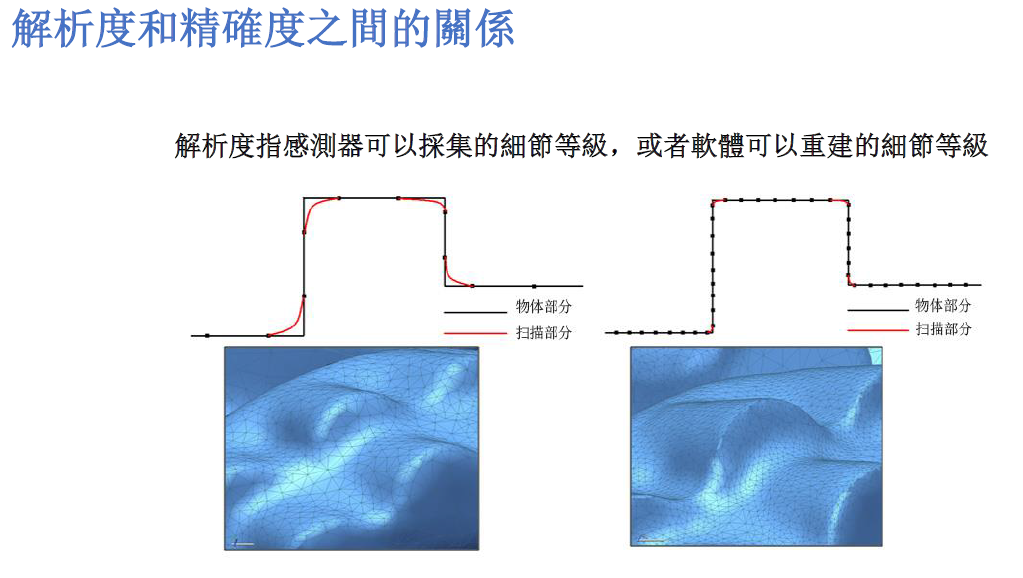

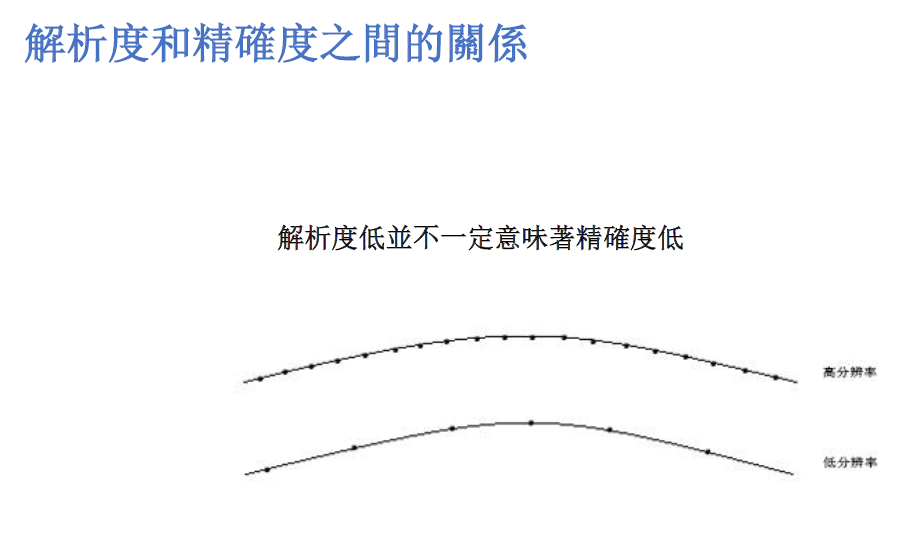

1. What is the resolution?

2. What is precision and accuracy?

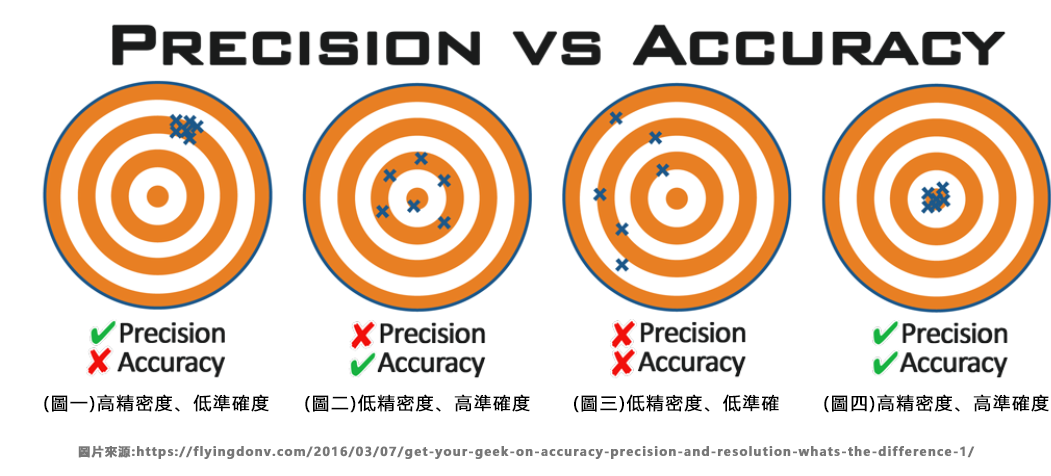

In surveying, accuracy of measurement is an index of authenticity of measurement, and it usually contains meanings such as precision and accuracy. Therefore, precision reflects the combined effects of nonsystematic and systematic errors.

Precision and accuracy are two words which often are used in science, engineering and statistics. In Chinese, because they are so close, they are usually almost the same. But in English, Precision and Accuracy are two seemingly different words. The most common example of the difference between precision and accuracy is target practice. If shooting three times, the bullet holes on the target paper may have four situations from left to right in the figure below, which can just be used to illustrate the precision and accuracy.

3. How can I determine if this is the scan specification I need?First, determine the tolerances established by the dimension of product, and then extend to determine whether there is a requirement for accessories to match the appropriate scanner.

Example 1: The requirements for scan and detection of automotive molds

First, determine whether it is a semi-finished product and has a reserved amount of finish. At this time, the tolerance condition is relatively low. If it needs the finishing milling, the specifications of the selected scanner must be more precise.

Example 2: The scan requirements for dolls and artwork

The application cases usually pay attention to the presentation of the shape rather than the precision. The choice of the scanners must consider the high resolution ratio, relatively low product level, and easy use.